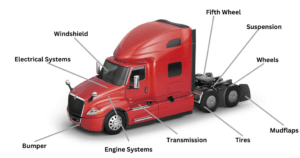

Semi Truck Parts Diagram

Semi-truck engines are among the most intricate mechanisms on the road. Composed of numerous components, each serving a specific role in generating power and facilitating smooth engine operation.

Given that trucks handle 72% of our daily consumed goods’ transportation, it’s vital to have a comprehensive understanding of the various components constituting your engine system.

In this guide, we’ll talk about the major parts of a semi-truck so as to provide you with insights into the functioning of your commercial engine.

Engine Systems

The engine systems comprise a complex array of trailer parts such as pistons, cylinders, crankshafts, differential components, drive shafts, and more. Each component plays a crucial role, and any irregularities in their function can impact the overall performance of the truck.

Proper maintenance is vital to ensure optimal performance and longevity. Regular oil changes, timely filter replacements, and scheduled maintenance checks will provide the engine with its routine care. This will help prevent potential breakdowns, ensure reliability during long hauls, and ultimately extend the truck’s lifespan.

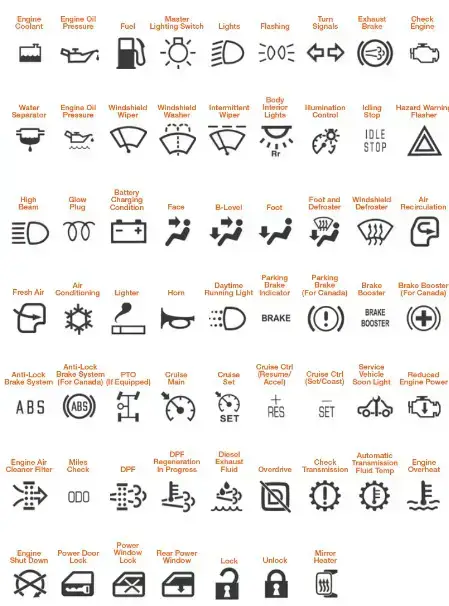

Electrical Systems

These are the semi-truck’s central control hub, making sure everything runs smoothly. They handle a bunch of important stuff, from firing up the engine to keeping the lights on and helping with navigation.

These systems work with batteries, alternators, wires, and fuses. Each piece has a job, like the batteries getting the engine started and the alternators keeping them charged up. The wires and the fuses make sure electricity gets where it needs to go, powering everything from the headlights to the gadgets inside.

Regularly carry out inspections, test batteries, and alternators, and ensure wiring integrity. These efforts prevent potential electrical issues that could lead to breakdowns or malfunctions, ensuring the truck’s reliability and safety on the road.

Fifth Wheel

The fifth wheel in a semi-truck acts as the connection point between the tractor unit and the trailer. This handy piece of equipment helps the truck turn and pivot while towing heavy loads. Its job is pretty straightforward: hitch and unhitch the semi-trailer swiftly. It’s a heavy plate that locks the trailer in place, making sure it stays connected when it needs to and comes off easily when it doesn’t. Without a well-maintained fifth wheel, trailers wouldn’t get anywhere.

To keep the fifth wheel running smoothly, regular checks and grease-ups are vital. Inspecting it for any wear and tear, adjusting the mechanism, and giving it a good greasing are part of its maintenance routine.

Transmission

Think of the transmission as the truck’s gear shifter. It plays a crucial role in regulating the engine’s power and transmitting it to the wheels. By using various gears it allows the truck to adjust to different speeds and navigate diverse terrains, whether climbing steep inclines or driving steadily on highways.

Manual transmissions use two to three countershafts to transfer engine power from the input to the output shaft. These countershafts distribute torque in different directions, lessening the stress on individual gears. On the other hand, automatic transmissions operate without a clutch pedal. The I-SHIFT transmission from Volvo is an example of automated manual transmission.

Regular checks and fluid changes are necessary to keep the transmission functioning optimally. Transmission fluid lubricates the internal components, reduces friction, and helps in heat dissipation. So, you need to ensure that it’s clean and has adequate lubrication. Also, inspecting for leaks, unusual noises, or difficulty in shifting gears will help you to catch potential issues early.

Suspension

The suspension system’s primary role involves managing the truck’s weight distribution and absorbing road shocks efficiently. Composed of components such as springs, shock absorbers, and linkages, this system works collectively to uphold the truck’s stability, improve its handling, and reduce vibrations. Besides ensuring a smoother ride for drivers, it also shields the truck’s valuable cargo from unnecessary jolts and impacts.

Ensuring the suspension’s proper upkeep is critical for safe and effective truck operation. Regular inspection of its components, such as assessing spring wear or shock absorber leaks, is vital. Additionally, you have to keep the moving heavy-duty truck parts lubricated, align the wheels, and maintain optimal tire pressure. You can get both aftermarket and original equipment parts (OEM) if you need to replace any parts.

Bumper

The bumper, positioned at both the front and rear of a truck, safeguards the vehicle’s exterior. It functions as a protective element intended to absorb impact in the event of minor accidents or collisions, shielding the truck’s internal components and enhancing overall safety.

Maintaining bumpers involves regular inspections for any signs of damage or wear. Check for dents, scratches, or cracks, as these can compromise the bumper’s integrity and effectiveness. Clean the bumper regularly to remove dirt, debris, or other contaminants that might accumulate. Repair or replace damaged bumpers promptly to ensure they continue to provide adequate protection.

Sleeper Cabin

The cab is the command center of a semi-truck. It’s like the driver’s second home on the road. This space not only houses the driver but also the truck’s controls, seating, and sleeping compartments. It’s where the driver navigates, controls the truck, and takes well-deserved rest breaks during long hauls.

Besides being the control hub, the cab provides a comfortable workspace for the driver. It offers visibility for safe driving, accommodating controls for air brakes, compressors, driveline fittings, converter, gear shifts, HVAC systems, power steering, and all the necessary gauges and displays to monitor the truck’s performance. Additionally, it provides a cozy resting place equipped with a bed, storage, and amenities to ensure the truck driver is refreshed and ready to hit the road.

Maintaining the cab involves a mix of functionality and comfort. Keep the interior clean and organized for the driver’s convenience. Regularly check on essential systems and controls within the cab for safety and efficiency. From making sure the lights and indicators are working properly to checking the comfort features, such as the heating and cooling systems.

Steering System

The steering system in a semi-truck is what makes the massive wheels turn smoothly in the right direction.

This system converts the driver’s input into movement by linking the steering wheel to the truck’s wheels. Whether it’s a tight curve or a gentle turn, the steering system ensures that the truck responds accurately to the driver’s commands.

To keep this system in top-notch condition, regular maintenance is key. Inspect the steering components for wear and tear, check the fluid levels, and ensure proper wheel alignment. Also, grease and adjust steering parts at recommended intervals to prevent problems down the road.

When you carry out scheduled maintenance, you’ll have smooth runs and enhanced safety during fleet operation.

Fuel System

This system ensures that the engine receives the right amount of fuel at the right time. Using a network of pipes and filters, the fuel is pumped toward the engine. The engine’s performance relies heavily on the proper functioning of this system.

At present, the primary power source for semi-trucks remains the diesel engine. While some truck fleets have considered alternative natural gas options like LNG, the infrastructure for fueling and maintenance doesn’t match that of diesel. Irrespective of the engine type, modern-day engines are universally governed by computerized controls.

Regular checks on fuel filters, lines, and tanks are essential. Filters should be changed periodically to prevent any dirt from getting into the engine. Moreover, keep an eye on fuel quality and ensure the tanks are in good condition.

Frame

The frame of a semi-truck provides the structural support needed to hold everything together. It bears the weight of the truck’s valuable components, such as the engine and cargo. It brings stability, empowering it to carry heavy loads and brave challenging terrain with ease.

Maintaining the frame is essential to ensure the truck’s structural integrity and longevity. Regularly check for signs of wear, rust, or damage. It’s important to promptly repair any cracks, corrosion, or weakened areas to prevent further deterioration. Additionally, proper cleaning and rust prevention treatments can help extend the frame’s lifespan.

Wheels

Wheels are a fundamental part of a truck, serving as the point of contact between the vehicle and the road. These circular components provide motion and support the truck’s weight, making them essential for its functionality.

Their primary function is to facilitate movement by rotating on an axle. Truck wheels are designed to withstand heavy loads and various road conditions, ensuring stability and safe transportation.

To maintain a truck’s wheels, inspecting them for signs of damage, including cracks, dents, or uneven wear patterns, is important. Properly inflated tires contribute to better fuel efficiency and overall handling. Additionally, routine tire rotation and balancing can help extend the life of the wheels and tires by ensuring even wear.

Tires

These are the interface between the truck and the road. Tires are not just circular rubber objects; they’re specially designed to endure tremendous pressure and carry the weight of the entire truck along with its cargo. These parts provide traction, allowing the vehicle to grip the road, even in adverse weather conditions.

The tire’s tread pattern, depth, and composition are engineered to channel water away from the tire’s surface, improving grip and hydroplaning during wet conditions. Also, the right tires contribute significantly to fuel efficiency and smooth driving experiences.

Regular maintenance is imperative to tire longevity and optimal performance. Incorrect tire pressure affects fuel efficiency and traction. Inspect for any cuts, punctures, or irregular wear, as these issues can compromise safety. Rotating tires regularly ensures even wear across all tires, extending their lifespan.

Proper wheel alignment also plays a significant role in preventing uneven wear and preserving tire integrity. Moreover, maintaining the right tread depth is essential for safe driving, especially on slippery roads.

Mud Flaps

Mudflaps, often an overlooked part of a truck, serve a significant role in safeguarding the vehicle and motorists from road debris, mud, water, and other elements that might get kicked up by the truck’s wheels. Well positioned behind each wheel, mud flaps are a protective addition to trucks. They help minimize the damage caused to the vehicle’s exterior paint, the undercarriage, and other vehicles on the road.

Mud flaps are relatively low-maintenance, but regular checks are important to ensure their effectiveness. Inspect them periodically for damage, such as cracks, tears, or signs of wear. Clean them regularly to remove any accumulated dirt or debris. Ensure that they remain securely attached to the truck; loose or missing mud flaps should be replaced promptly to maintain their protective function.

Windshield

The windshield’s primary function is to shield the driver and passengers from wind, rain, debris, and other flying objects on the road. Maintaining the windshield will ensure that the driver will have a clear and unobstructed view of the road. Clean it regularly to remove dirt, bugs, and grime that can accumulate and hinder visibility. Also, address small chips or cracks promptly to prevent them from spreading and causing further damage.

Cooling System

This vital system ensures that the engine doesn’t overheat. It does this by circulating coolant, usually a mixture of water and antifreeze, through the engine and radiator. As the coolant flows through the engine, it absorbs heat and then travels to the radiator, where it releases that heat into the air. This process prevents the engine from overheating, which can cause severe damage and lead to breakdowns.

Keep the cooling system in tip-top shape by having regular checks and maintenance. Inspect for leaks, ensure proper coolant levels, and examine the radiator and hoses for damage. Also, change the coolant periodically and replace the thermostat for the system’s proper functioning.

Do You Need Truck Maintenance?

Do you want to expand your understanding of your trucker’s intricate components? By doing so, you’ll boost your knowledge and be in a better position to make informed decisions regarding upkeep and repairs. At Kyrish Truck Centers, we offer specialized maintenance solutions tailored to your semi-truck needs.

Get to learn how our maintenance services can keep your fleet in top condition to ensure smooth rides and optimized performance on the road.

Why not reach out to us today?