How to Set up a Fleet Maintenance Program

Are you tired of dealing with surprise breakdowns and endless bills? When costs suddenly go up because of poor maintenance, efficiency decreases, and your trucks aren’t as reliable as they used to be.

A solid fleet maintenance program will keep everything running smoothly, saving money and ensuring your fleet is always ready for your next big contract.

If you are a pro at fleet management or just getting started, you want a program that doesn’t just do the job—it excels. This guide will look at the how-tos of setting up a fleet maintenance program that answers your immediate questions like—how do you plan fleet maintenance? How do you create a maintenance program?

This guide will also equip you with the knowledge to anticipate challenges and make informed decisions.

Why Set Up a Fleet Maintenance Program?

knowing your trucks are always ready is critical to planning your schedule and controlling costs. That’s why sticking to a regular maintenance schedule is a must. If you skip routine maintenance, your trucks could break down unexpectedly.

Some trucks break down more often and need more costly repairs if they don’t get regular maintenance. This could lead to unplanned downtime and safety concerns. Ignoring maintenance could also expose you to more driver injuries, incidents of liability, and other serious crises.

Preventive maintenance is just as important as keeping your drivers safe. If a truck becomes unsafe because it wasn’t maintained properly, fleet managers could be held responsible for letting employees use it.

It’s crucial to ensure your trucks are safe to drive. If there’s a serious accident and investigators find out it was because of a faulty braking system or other maintenance issues, you could face legal consequences if you haven’t kept up with maintenance records.

Lastly, a well-maintained fleet is also more environmentally friendly. Efficient engines emit less pollution, and regular maintenance can identify and fix issues that may lead to higher emissions. This aligns with increasing regulatory and societal expectations for businesses to operate sustainably.

Start with a Complete Inspection of Your Fleet

Conducting a detailed fleet inspection enables you to identify any existing issues or potential concerns before they escalate into major headaches. Addressing these issues upfront ensures fewer surprises and keeps your business operations running seamlessly.

Recognizing that not every truck in your fleet requires the same level of care is important. By checking each truck, one by one, you can see which ones need extra care. This varies based on age, usage frequency, and overall condition. Some trucks might need more frequent check-ups, or certain parts may wear out quicker.

You can set aside money and plan when to fix things without interfering with your regular operations.

Following safety rules and meeting regulations is crucial, especially in tightly regulated industries like transportation and logistics. With these data-driven insights, you can whip up a maintenance plan that is way more efficient and effective and increases your fleet’s lifespan.

Set Maintenance Schedules Based On Your Specific Fleet Trucks

Every truck is different, so their maintenance needs vary too. Customizing your maintenance schedules ensures each truck gets the care needed to stay in top condition.

Standard maintenance plans might not cover all your fleet’s unique features or demands. By adapting your schedule, you can address specific issues or requirements relevant to your fleet. These schedules help you optimize your resources and avoid unnecessary costs. You can focus on the tasks that matter most for your trucks, saving time and money in the long run.

Build a More Effective Program Over Time

Keep Detailed Records

Gather data from your preventive maintenance activities and expenses and compile a comprehensive report using an Excel spreadsheet. This report should be generated monthly and presented to senior management for assessment. Include details on the total number of completed truck tasks, both planned and unplanned, along with specifics on the types of maintenance performed.

Additionally, incorporate any variable operating costs related to fleet usage scenarios, such as operating in off-road conditions, extensive idling, or towing trailers.

Clearly outline any expectations, requirements, and scheduled intervals for maintenance tasks. This information is invaluable for identifying patterns, tracking trends, and understanding the overall health of your fleet.

For instance, you might see that some types of trucks need repairs more often or that certain parts tend to break down after a certain mileage. Having detailed records lets you plan maintenance ahead of time using past data instead of waiting for issues to pop up.

And don’t overlook compliance—detailed records help you stay in line with industry regulations, keeping you out of trouble.

Optimize Your Part Inventories

Keeping the parts you need nearby speeds up fixes, avoiding delays, and keeping everything on track. Having the right number of parts saves you money and prevents them from running out when you need them the most. Plus, it ensures you’re always prepared to keep your trucks in shape.

When technicians can quickly get the needed parts, repairs happen faster, keeping your operations smooth and getting your trucks back on the road sooner. By checking your maintenance records and how your trucks are used, you can predict what parts you’ll need down the line.

Maintaining optimized part inventories also involves building strong relationships with vendors and suppliers. This leads to better deals, smoother ordering, and quick delivery. And having a dependable supplier on standby? That can be a lifesaver when you’re in a tight spot!

Work with Your Drivers

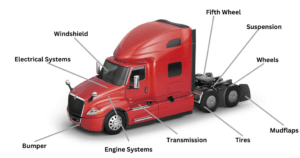

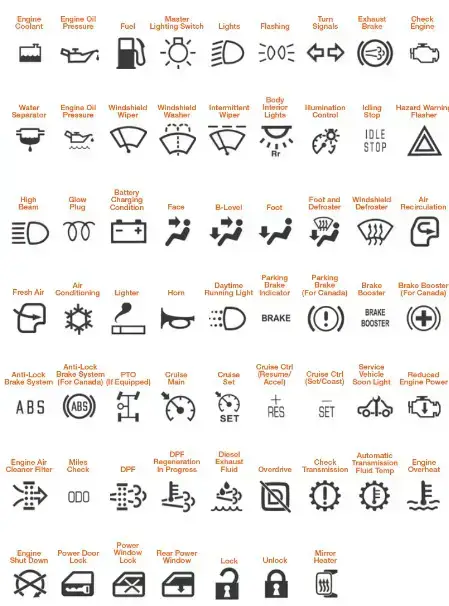

The driver plays a crucial role in preventing unexpected breakdowns and repairs by promptly reporting truck issues to fleet management. Drivers should regularly monitor the following vehicle systems:

- Drivability factors such as rough idling or misfires

- Truck body condition, including cleanliness, glass, and body damage.

- Safety features like windshield wipers, horns, steering, tires, and brakes.

- Parts such as the exhaust system, hoses, fuel system, etc

- Miscellaneous repair items like heaters and radios

Ensuring drivers take responsibility for inspecting these components is crucial, as an effective fleet maintenance program hinges on their attentiveness. Failing to check the trucks before, during, and after trips may lead to unnoticed problems, potentially causing breakdowns or unsafe situations.

Training and accountability are key components. Drivers need proper training on inspection procedures and must be held responsible for failing to report truck problems. This requires support from all departments and senior management.

Track Metrics

Track your maintenance costs to stay on top of expenses, whether for routine upkeep or unforeseen fixes. Monitor how long each truck spends in the shop for maintenance or repairs. Excessive downtime might signal areas where your maintenance process could be improved or recurring problems that need attention.

Ensure your trucks adhere to their preventive maintenance schedules to avoid missed check-ups or overdue services. Catching up on maintenance tasks promptly helps prevent breakdowns and keep safety concerns at bay. Track metrics related to truck reliability, such as the frequency of breakdowns or roadside assistance calls. Gather feedback from drivers regarding their experience with truck maintenance and repair processes.

Make Use of Technology

Truck preventive maintenance (PM) can be arranged either manually or through the use of fleet maintenance software, which is an automated computer system. Manual methods can be burdensome and time-consuming, particularly for larger fleets.

Nowadays, even small fleets can afford technology, often through a prepaid maintenance plan. Some managers are using telematics and Computerized Maintenance Management Systems (CMMS).

Affordable software systems are available from reputable companies specializing in fleet management systems. As for hardware, most companies have an IT department that can provide fleet management with suitable computers or hire an IT expert for assistance.

Regardless of which scheduling method you opt for, investing in a system that can be tailored to meet your unique application needs is crucial.

Avoid Shortcuts

Educating in-house technicians on the significance of conducting thorough preventive maintenance services is essential. The effectiveness of the PM service relies heavily on the individual performing it, so it’s crucial to avoid taking shortcuts. Each truck must be serviced proactively by the technician to minimize breakdowns and repairs.

If your fleet operation delegates preventive maintenance tasks to an external provider, consider partnering with a local vendor specializing in maintaining fleet trucks. Meeting with the service manager to address various PM service-related matters is advisable.

Provide the vendor with your PM checklist. Many shops focus primarily on breakdown maintenance rather than preventive maintenance. Communicate your specific expectations to the maintenance facility using your fleet preventive maintenance program. Also, inquire about fleet discounts for parts and track the number of repairs, jumpstarts, breakdowns, tows, oil changes, emergency, and collision repairs for unscheduled maintenance.

Understand the Difference Between Scheduled and Unscheduled Maintenance

Scheduled maintenance involves proactive missions like regular services and truck inspections, aiming to catch and fix minor issues before they become major problems.

On the other hand, unscheduled maintenance tends to be more costly and leads to significant downtime. It often happens due to incidents on the road or neglect from drivers. Encouraging drivers to perform routine truck checks can help avoid expensive and scheduled maintenance events and turn them into less costly ones.

The majority of maintenance tasks should be scheduled PM. By monitoring and comparing scheduled and unscheduled maintenance activities, you can generate a detailed report on the effectiveness of your PM program.

It may not be possible to prevent all unscheduled maintenance incidents, such as when drivers accidentally leave interior lights on, leading to a dead battery. Analyzing breakdown maintenance data allows for PM frequency adjustments and maintenance checklist modifications to better align with the fleet’s needs.

Should You Hire a Partner to Handle Fleet Service?

A fleet service provider oversees logistical duties and ensures truck readiness for your fleet. They guarantee that your trucks operate efficiently and effectively, both financially and operationally. While businesses with fewer trucks may handle fleet management alongside other business tasks, this balancing act becomes challenging beyond the 24th truck.

Each day presents an opportunity to enlist a fleet service provider, but it becomes increasingly critical as your fleet exceeds a dozen trucks with potential for expansion. Some of the major benefits of hiring a fleet service provider include:

- Ensuring maintenance quality for your fleet

These providers can thoroughly evaluate your maintenance service providers to ensure that only skilled and dependable mechanics handle your trucks. Regular fleet maintenance ensures a return on investment but with one condition: strict schedule adherence. Hence, having someone oversee your schedules and monitor maintenance expenses is essential.

- Tracking driver performance

Consider hiring fleet service providers to actively monitor your drivers’ truck-use behavior. They’ll meticulously assess your fleet operators to ensure strict adherence to the best driving practices. Moreover, fleet service providers will identify and collaborate with efficient drivers to develop long-term plans and strategies that optimize your fleet operations.

- Overseeing vehicle procurement and parts acquisition

They’ll explore various options when purchasing truck materials in bulk to secure the best discounts and deals for you. A fleet service provider is adept at negotiating deals and leveraging promotions when sourcing parts, ensuring your company obtains top-quality items at reasonable prices.

- Scaling your business

The advantages of enlisting the services of fleet service providers surpass the associated costs. You can dedicate less time to worrying about your fleet and instead focus on critical business aspects such as evaluating products or services, developing strategies, and exploring expansion opportunities.

- Keeping up with vehicle registration and inspection management

Fleet service providers efficiently handle annual inspections, deadlines, and registration renewals, preventing oversights that could result in costly fines.

- Staying updated on new technology and trends

Fleet service providers will keep you informed about emerging trends in trucks relying on superior services and products to maintain your fleet stock condition year after year. From maps to fuel cards to GPS trackers and digital payment solutions, they’ll ensure that your fleet benefits from new truck upgrades and enhancements.

Ask us about Fleet Services

Ultimately, partnering with professionals for your fleet requirements is a smart move. With their knowledge, convenience, and affordability, you can be confident that your trucks are well cared for.

Do you need routine maintenance, immediate repairs, or comprehensive fleet management assistance? We ensure that our services align perfectly with your specific situation.

For more information about our fleet services and how we can help you establish a successful fleet maintenance program, contact us today!